All instructions and recommendations should be followed for a satisfactory installation. A minimum of a 48-hour acclimation period of the material is required prior to installation. The floor covering should be acclimated and installed in a climate-controlled environment with a temperature between 55°F and 85°F, (13°C and 29°C) or average temperature of 70°F, (21.1°C)

Subfloor information

All subfloors must be clean, flat, dry and structurally sound. The correct preparation of the subfloor is a major part of a successful installation. Subfloor must be flat – 3/16" in 10' or 1/8" in 6'.

Wood Subfloors

Do not install material over wood subfloors that lay directly on concrete or over dimensional lumber or plywood used over concrete.

Refer to ASTM F1482 for panel underlayment recommendations.

Concrete Subfloors

New and existing concrete subfloors should meet the guidelines of the latest edition of ACI 302 and ASTM F710, “Standard practice for preparing concrete floors to receive resilient flooring”, available from the American Society for testing and materials, 100 BARR HARBOR DRIVE, WEST CONSHOHOCKEN, PA 19428; 610-832-9585;

level for ASTM 2170 In-situ Relative humidity test method - 90%.

NOTE: IT MAY NOT BE THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO CONDUCT THESE TESTS. IT IS, HOWEV- ER, THE FLOOR COVERING INSTALLER'S RESPONSIBILITY TO MAKE SURE THESE TESTS HAVE BEEN CONDUCTED, AND THAT THE RESULTS ARE ACCEPTABLE PRIOR TO INSTALLING THE FLOOR COVERING. WHEN MOISTURE TESTS ARE CONDUCTED, IT INDICATES THE CONDITIONS ONLY AT THE TIME OF THE TEST.

Lightweight Concrete

All recommendations and guarantees as to the suitability and performance of lightweight concrete under resilient flooring are the responsibility of the lightweight concrete manufacturer. The installer of the lightweight product may be required to be authorized or certified by the manufacturer. Correct on-site mixing ratios and properly functioning pumping equipment are critical. To ensure proper mixture, slump testing is recommended.

Radiant Heat: Hydronic only - Radiant heat components must have a minimum of 1/2" separation from the product. This is the only type of radiant heat system that is approved. Radiant heat system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture within the concrete. Three days prior to installation lower the temperature to 65°F, after installation gradually increase the temperature in increments of 5°F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating.

Existing Floor Coverings

Flooring can be installed over most existing hard-surface floor coverings, provided that the existing floor surface is fully adhered, clean, flat, dry, structurally sound, and free of deflection.

Raised Access Panel Subfloors

If needed overlay the panels with a 1⁄4” (6 mm) plywood and properly fasten to the access panels prior to the installation of the floor covering. Prior to underlayment installation, repair any loose or unstable panels. Use the appropriate installation methods for the product.

Installation

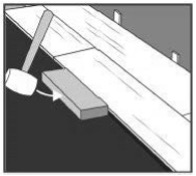

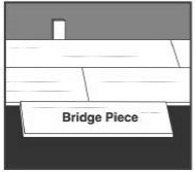

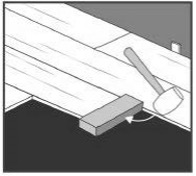

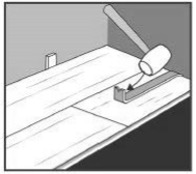

Tools: Tape Measure, Utility Knife, Jigsaw, Tapping Block or Rubber Mallet, Pull Bar, 1/4" Spacers, T-Square, Safety Glasses, Broom or Vacuum and, if necessary, tools for subfloor repair.

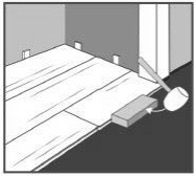

Floating Installation

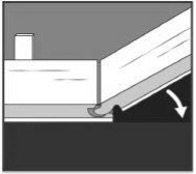

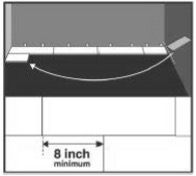

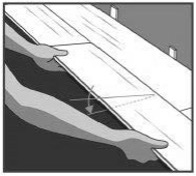

SPC plank flooring is designed to be installed utilizing the floating method. Proper expansion space 1/4” (6.35 mm) is required. For installation in areas larger than 50’x 50’, 2500 sq. ft. provide a minimum expansion space of 1/2” (12.7 mm) around the perimeter. Undercut all doorjambs. Do not fasten wall moldings and or transition strips to the planks.

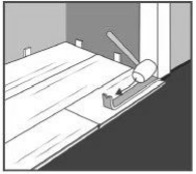

Glue Down Installation

SPC products are approved for glue down installation over approved wood and concrete substrates. Follow adhesive label application instructions. Install flooring into wet adhesive. Maintain 1/4” (6.35 mm) perimeter expansion space. Refer to adhesive label for moisture limits of the adhesive. Roll flooring immediately after installation with a 100 lbs. 3‐section roller.

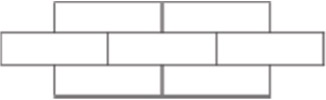

Tile patterns must be installed in a staggered (offset) brick pattern. Minimum 1/3 offset 1/2 offset is preferred.

Completion

1. Protect all exposed edges of the flooring by installing wall molding and/or transition strips. Make sure that no plank will be secured in any way to the subfloor.

2. For wet areas such as bathrooms caulk the perimeter of the floor with a flexible silicone caulk.

3. Protect the finished flooring from exposure to direct sunlight to reduce fading and thermal expansion.

Radiant Heat:

SPC / LVP Over Radiant Heat:

Radiant Heating: Radiant-heated subfloor systems can be concrete, wood or a

combination of both.

The heating systems components must have a minimum of 1/2″ separation from the heating system to the flooring covering product. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Three days prior to installation lower the temperature to 65 degrees. After installation, gradually increase the temperature in increments of 5° F to avoid overheating. Maximum operating temperature should never exceed 85°F. Use of an in-floor temperature sensor is recommended to avoid overheating. Contact the manufacturer of your radiant heating system for further recommendations.

Warning: Heating mats work very well under carpet, tile, and stone. However, we do not recommend having them placed directly underneath the Vinyl SPC or LVP floor. It is best to install Vinyl SPC flooring over hydro-based radiant heating systems.

LVP (dry-back, glue down) specific:

Use only recommended flooring adhesive over manufacturer’s recommended plywood substrate. The system must be on and operational for at least 2 weeks prior to installation to reduce residual moisture. Turn the heat off for 24 hours before and during installation, and 24 hours after installation when installing over radiant heated subfloors. Failure to turn the heat off may result in shortened working time of the adhesive.

Floor temperature must never exceed 85°F (30°C).

Failure to strictly follow adhesive manufacturer’s guidelines may result in failure and void warranty.